Overland conveyor belt: Conventional large-capacity, long-distance overland conveyors use a steel cord belt with a single layer of parallel steel cords to carry the belt tension.

However, technical risks are still associated with these systems at the ultimate limits of existing knowledge and experience. The baseline is a solid foundation of design and operation experience. The technology and components are readily available from many suppliers.

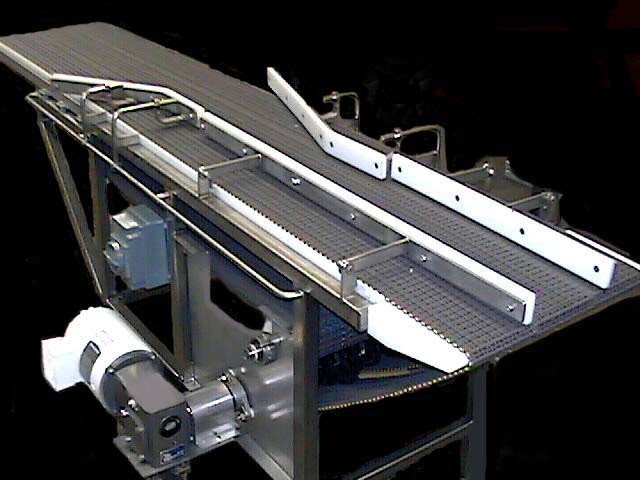

The technology has been developing over the past decades and continues to do so. Options for overland conveying vary according to numerous factors, including capacity, length, terrain, geotechnical properties, and the environment. SKE can help identify and eliminate these issues. Or perhaps one or two problems always seem to pop up at regular intervals. Survey and Assessments: If conveyor downtime is eating into your production, a plant wide audit might reveal some simple changes that could have huge benefits. We know what the problems are and how to solve them. SKE pioneered the use of DEM in belt conveyor transfer design. Transfer Chute Design by Discrete Element Method: The simulation of bulk materials flowing through transfer chutes is one of the most difficult engineering problems conveyor engineers face. Long Distance Conveyor Design: Design of a conveyor system focused on proper major component selection through design trade-off studies and customer feedback.ĭynamic Analysis of Conveyors: Avoid common conveyor design flaws such as belt sag and drive slip by accurately modeling the starting and stopping of a conveyor while accounting for the change in stretch of the belt. Our desire to collaborate and move the conveyor industry forward has lead to pioneering work with: The routing of the overland belt conveyor system is adapted to the geographic and topographic conditions by combining horizontal and vertical curves. Rough, mountainous and fragmented terrain with extreme differences in height is nothing overland belt conveyors can’t handle. In modern industry, the overland belt conveyor system are widely designed for handling bulk materials like iron ore, copper ore, bauxite, limestone, sand, aggregate, etc.

0 kommentar(er)

0 kommentar(er)